3D Printing: Building Shapes from Scratch

3D printing is revolutionizing industries by enabling faster production, customized designs, and reducing waste. This technology allows for layer-by-layer construction of objects, leading to innovative solutions in fields like healthcare, manufacturing, and even construction. Despite challenges such as quality control and material limitations, ongoing innovations are overcoming these hurdles, making 3D printing a key player in the future of manufacturing and design.

Have you ever tried creating something out of thin air? 3D Printing makes that possible! From prototypes to artificial organs, the possibilities are endless. Let’s dive in!

Understanding 3D Printing Technology

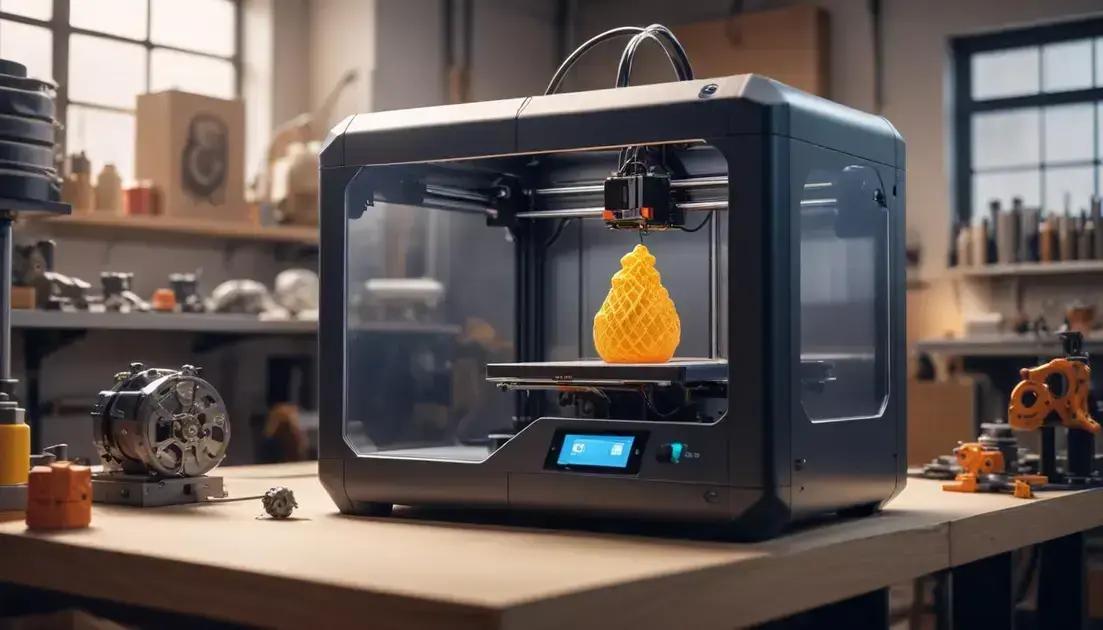

Understanding 3D Printing Technology is an exciting topic. It allows people to turn digital designs into real objects. This process starts with a 3D model created on a computer. These models can be made using various software tools. Once the model is ready, it’s sent to a 3D printer.

3D printers work by layering materials. They can use plastic, metal, and even food! The printer lays down thin layers one at a time. As it builds up these layers, the object takes shape. This method is different from traditional manufacturing.

Many industries benefit from 3D printing. For example, in healthcare, 3D printing can create prosthetics tailored to individual needs. In construction, it may help produce building components quickly.

How 3D Printing Works

Here’s how it typically works: First, you create a design. You can use 3D modeling software like Blender or Tinkercad. After that, the design is sliced into layers using slicing software.

The sliced file is sent to the printer. The printer heats the material and deposits it layer by layer. Each new layer bonds with the previous one. This continues until the object is complete.

This technology is changing how we think about production. It’s faster and often cheaper. Plus, it allows for unique designs that are hard to create in other ways.

Applications of 3D Printing

These days, 3D printing has many exciting applications. In fashion, designers create custom pieces that you can’t find anywhere else. In automotive, companies print parts that fit perfectly into their cars.

Even toys can be made this way! Kids can design their toys and print them. This makes learning fun and interactive. Schools use 3D printers to teach students about design.

In summary, 3D printing technology is a fascinating field. It opens up many possibilities for innovation. As more people learn about it, the future of 3D printing looks bright.

Applications in Prototyping

Applications in Prototyping showcase how 3D printing is changing the design process. Prototyping is essential in many fields, like engineering and design. It helps create models to test ideas before full production.

With 3D printing, prototypes are made quickly. Designers can make changes and print new versions in hours. This speeds up the development process significantly. Traditional methods can take weeks or even months.

In industries like automotive, companies use 3D printing to test new parts and designs. Instead of expensive molds, they can create prototypes at a lower cost. This makes it easier to explore new concepts and improve designs.

In the tech world, startups use prototyping to bring their ideas to life. They can create functional devices to show to investors. This first version helps get feedback and make necessary adjustments.

Why Prototyping Matters

Prototyping allows teams to experiment with ideas. When they see a model, they can spot flaws or improvement areas early on. This saves time and reduces costs in the long run.

Using 3D printing for prototyping also encourages creativity. Designers can try unique shapes and features they might avoid with traditional methods. This freedom leads to better, more innovative products.

Overall, the applications of 3D printing in prototyping are vast. They help bring ideas to life faster and more effectively. This technology is a game-changer for industries looking to innovate.

The Future of Artificial Organs

The Future of Artificial Organs is an exciting area of 3D printing. This technology is changing how we think about healthcare. Artificial organs can help patients who need transplants. They make it possible to create organs tailored to individual needs.

With 3D printing, doctors can design organs that match a patient’s specific body. This means fewer complications and better outcomes. These organs can be made from biocompatible materials. These materials work well with the body and reduce rejection risks.

Many companies are researching this field. They’re working on organs like kidneys, livers, and even hearts. Using 3D printing, scientists can test their designs quickly. They can create prototypes that mimic the function of real organs.

Benefits of 3D Printed Organs

One major benefit is solving the organ shortage crisis. Thousands of people wait for organ transplants each year. With 3D printed organs, fewer people would need to wait. This could save lives and improve quality of life for many.

Another advantage is customizing organs. Doctors can create organs that fit perfectly for each patient. This makes surgeries easier and recovery faster. Personalized medicine is the future of healthcare, and 3D printing supports this vision.

The future of artificial organs also includes the ability to grow tissues. Researchers are developing ways to print living cells. This can lead to fully functional organs that truly integrate with the body.

Overall, the potential of 3D printing for artificial organs is vast. This technology can revolutionize how we think about surgeries and healthcare.

Industrial Impact

Industrial Impact of 3D printing is significant and far-reaching. This technology is changing how industries operate. Many sectors are adopting 3D printing to enhance their production processes.

In manufacturing, 3D printing reduces waste. Traditional methods often create excess materials. But with 3D printing, objects are built layer by layer. This means only the needed amount of material is used.

Another impact is speed. Companies can produce parts faster. Instead of waiting weeks for components, they can print them in a matter of hours. This speeds up the entire production timeline.

Customization and Flexibility

Customization is another major benefit. Businesses can quickly create unique parts or products tailored to specific clients. This level of flexibility wasn’t possible before.

Additionally, 3D printing supports quick design changes. If a design needs adjustment, it can be modified in the software and reprinted. This saves time and resources compared to traditional methods.

In the aerospace industry, for instance, companies use 3D printing for lightweight components. These parts improve fuel efficiency and reduce costs. This application shows how industries are evolving.

Moreover, 3D printing has made an impact in the construction industry. Builders are starting to print entire homes. This can save a lot of labor costs and time on-site.

In summary, the industrial impact of 3D printing is profound. It’s reshaping how products are designed and manufactured across various sectors.

Challenges and Innovations

Challenges and Innovations in 3D printing are important to understand. While this technology offers many benefits, it also brings some challenges. One major challenge is quality control. Ensuring each printed item meets high standards is crucial.

Another challenge is material limitations. Not all materials are suitable for 3D printing. Developers must find and create new materials that can handle specific tasks or conditions. This can be a time-consuming process.

Additionally, the speed of 3D printers varies. Some printers can produce items quickly, while others take longer. Finding the right balance between speed and quality is essential.

Regulatory and Safety Concerns

Regulations can also pose challenges. As 3D printing grows, governments need to create rules. These rules must address safety and patents. It’s important to protect designs while encouraging innovation.

However, with challenges often come innovations. Researchers are constantly finding ways to improve the process. For instance, new printing technologies are emerging. These technologies aim to enhance speed, efficiency, and material options.

Companies are developing better software too. This software helps designers create more complex and efficient models. As software improves, it opens up new possibilities for creativity.

Collaboration between businesses, researchers, and governments can drive progress. Working together can lead to innovative solutions that benefit everyone.

In summary, while challenges exist, they also push for growth and creativity in the world of 3D printing.

Conclusion

In conclusion, the impact of 3D printing on industries is enormous. This technology opens new doors for innovation and efficiency across various fields. While there are challenges, like quality control and material limitations, the innovations being developed help overcome these hurdles.

As businesses continue to adopt 3D printing, they can create customized products faster and at a lower cost. This not only benefits companies but also improves the experience for customers. The future of 3D printing is bright as it continues to change how we design and produce items.

By embracing these advancements, industries can stay competitive and meet increasing demands. In the end, understanding and tackling the challenges will propel us further into the exciting future of 3D printing.